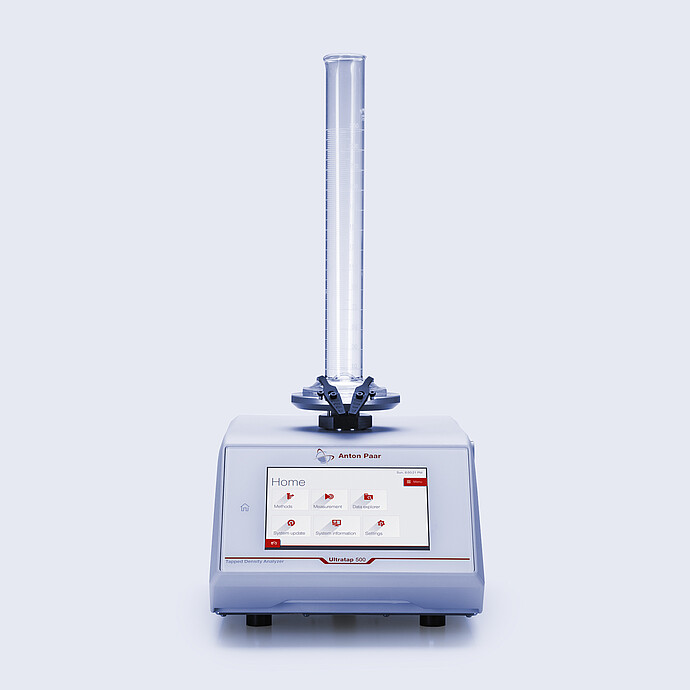

Tap Density Tester:

Ultratap

- One tapping station available

- 25 million taps, three-year warranty for unmatched durability

- Supports all major standards, ensuring compliance

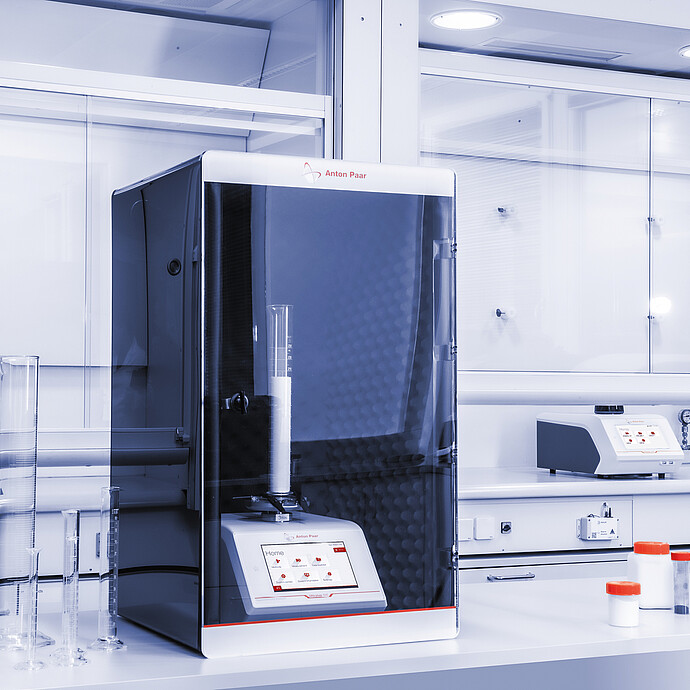

- Quiet operation, optional noise reduction for comfort

- Magnetic drop height adapter, quick cylinder setup; automated reports

The Ultratap 500 series of tap density testers delivers unmatched durability with guaranteed 25 million taps and a three-year warranty for long-lasting reliability. Designed for full compliance with major industry standards, they offer 24 pre-stored methods. They are also 90 % quieter, offering the lowest noise levels on the market. With TruLock straps for quick cylinder setup, an intuitive touchscreen, and automated reporting of key parameters, our instruments ensure a seamless experience every time.

Key features

Durable: 25 million taps without loss of calibration

Our tap density testers consistently deliver high-quality results you can depend on. The Ultratap 500 series guarantees up to 25 million taps without losing calibration, offering the highest durability on the market. To further ensure your confidence, our instruments come with a three-year warranty, assuring reliable performance for years to come.

Compliant: Benefit from a complete range of standard methods

The Ultratap 500 series covers standard major measurement methods, including USP 616 methods 1, 2, and 3, providing the widest range of industry standards in a single instrument. With 24 built-in ASTM, ISO, and USP methods, integrated user management, and automatic drop height detection, the tap density testers ensure full compliance while minimizing human error, resulting in more reliable and accurate results.

Easy: The best operator experience on the market

The tap density testers offer an exceptional combination of software and hardware. The TruLock straps allow you to securely attach any cylinder with a single motion. The integrated touchscreen, and on-device software, provide instant access to all standard methods, along with the ability to create custom methods. Automatically generate reports with key parameters such as bulk density, Carr’s Compressibility Index, and the Hausner Ratio, ensuring comprehensive and accurate data every time.

Quiet: 90 % quieter than any other tap density tester

Our tap density testers are as quiet as common household appliances, eliminating the need for hearing protection. Designed with noise reduction in mind, they operate at significantly lower decibel levels (90 % quieter) than any other tap density tester on the market. For even greater sound control, an optional noise reduction cabinet is available.

Specifications

| PERFORMANCE | Ultratap 500 Standard | Ultratap 500 Twin |

| Stations | 1 | 2 |

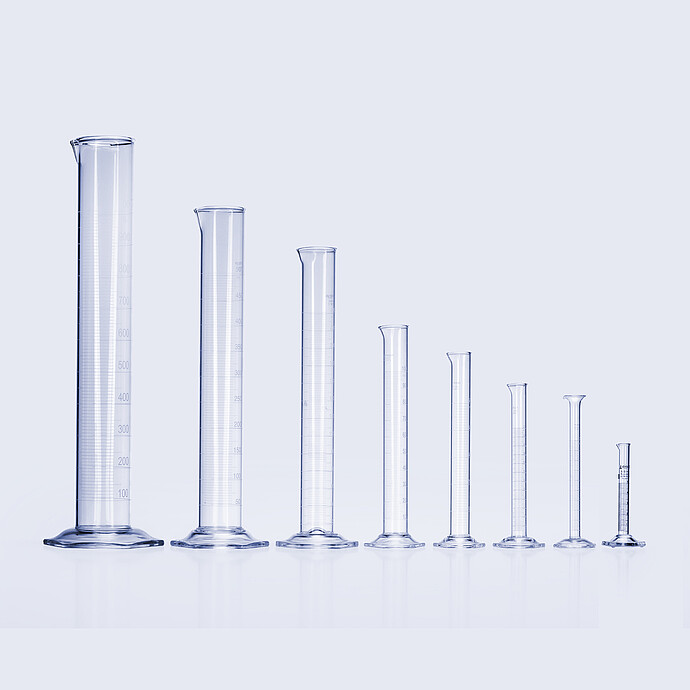

| Cylinder sizes accommodated | 250 mL standard 5, 10, 25, 50, 100, 250, 500, 1,000 mL1) | |

| Tap speed | User configurable 50 to 350 taps/minute | |

| Drop height | 3 mm (0.12 inch) ± 0.2 mm or 14 mm (0.55 inch) ± 1 mm | |

| Sound level | 65 dB (58 dB with optional noise reduction cabinet) | 68 dB (58 dB with optional noise reduction cabinet) |

| Tap mode | User configurable by time (1 second to 999 minutes) or number of taps (1 to 99,999) | |

| User interface | 7-inch TFT WVGA (800 x 480 pixels); PCAP touchscreen | |

| User management | Included (with password protection) | |

| USB ports | 2 | |

| Supported input devices | Barcode reader, keyboard, mouse, touchscreen | |

| Balance and printer connection | Yes (via USB port) | |

| Built-in calculations | Bulk density, Carr’s compressibility index, Hausner ratio, tapped density | |

| Storage capacity | 1,000 reports/100 methods | |

| Built-in methods | 24 | |

| PHYSICAL AND UTILITIES | ||

| Dimensions | Height: 228.6 mm (9 inches) no cylinder/vessel, 188 mm (7.4 inches) to top of housing Width: 263.5 mm (10.4 inches) Depth: 361 mm (14.2 inches) | |

| Weight | 14.5 kg (32 pounds) | 17.6 kg (38.7 pounds) |

| ELECTRICAL | ||

| Voltage-External AC/DC adapter | Input AC: 100-240 V, 1.3 A Frequency: 50 / 60 Hz | |

| Instrument input | 24 VDC, 2.1 A, 51 W | 24 VDC, 2.6 A, 63 W |

| Over-voltage category | I (for the instrument) | |

| Connection | Grounded, single-phase outlet | |

| ENVIRONMENTAL | ||

| Temperature | 15 °C - 40 °C (59 °F - 104 °F) | |

| Relative humidity | 10%-80% RH non-condensing | |

1) The 500 and 1,000 mL graduated cylinders require the large platform and corresponding TruLock straps (sold separately

Standards

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

ISO

JIS

ASTM

Japanese Pharmacopoeia (JP)

MPIF

Standards

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

ISO

JIS

ASTM

Japanese Pharmacopoeia (JP)

MPIF

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

E-Book - Field Guide to Pharmaceutical Powder Characterization Application Reports

-

Material Brief: Instant Coffee - Tapped Density - Ultratap 500 series Application Reports

-

Material Brief: Lactose Powder – Tapped Density – Ultratap 500 series Application Reports

-

Material Brief: Metal Powder - Tapped Density - Ultratap 500 series Application Reports

-

Measuring Geometric Density without Mercury - Ultratap 500 series Application Reports

-

Ultratap 500 series brochure Brochures

-

Ultratap 500 series brochure (letter) Brochures

Similar products

Consumables

Consumables

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.